Eye Care

Subcategories

Eye Care Kits

Comprehensive Eye Emergency Response in Organised Packages

Eye care kits provide complete eye injury treatment solutions assembled in convenient packages addressing workplace eye emergencies across laboratories, manufacturing facilities, construction sites, and chemical handling environments throughout England, Scotland, Wales, and Northern Ireland. These comprehensive kits contain varied eye care supplies including emergency eyewash bottles, sterile eye pads and dressings, eye irrigation solutions, eye baths, and guidance materials, offering complete eye emergency capability in organised packages. High-risk organisations rely on eye care kits for comprehensive eye injury response, convenient organised supply storage, appropriate treatment capability for varied eye injuries, regulatory compliance support particularly COSHH, and professional eye safety demonstration. Modern eye care kits incorporate features including comprehensive contents addressing chemical splashes through foreign object injuries, organised layouts enabling rapid access during emergencies, clear guidance supporting appropriate treatment, durable containers suitable for workplace environments, and regulatory compliance support. The provision of eye care kits demonstrates commitment to eye safety preparedness particularly in hazardous environments, supports immediate comprehensive eye emergency response, enables professional management, and fulfils duty of care across environments with significant eye injury risks.

The implementation of eye care kits directly supports workplace eye safety, comprehensive emergency response capability, and demonstration of professional preparedness in eye hazard environments. Eye injuries, particularly chemical splashes, require immediate comprehensive treatment, making organised readily accessible provision essential in high-risk workplaces. Eye care kits address emergency requirements by providing complete treatment capability in organised packages, immediate irrigation capability critical for chemical injuries, sterile supplies preventing infection, professional emergency response demonstration, and efficiency through pre-assembled comprehensive contents. Applications include laboratories with chemical splash risks, manufacturing environments with eye hazards, construction sites with dust and particle risks, chemical handling facilities, and workplaces with identified significant eye injury risks. Organisations benefit from eye care kits through comprehensive eye emergency capability, convenient organised provision, regulatory compliance support particularly COSHH requirements for chemical handling, and professional safety demonstration. Modern eye care kits incorporate features such as emergency reference cards, varied eyewash volumes, and portable designs throughout England, Scotland, Wales, and Northern Ireland.

Selecting and implementing eye care kits requires eye hazard risk assessment, appropriate kit specification, and integration with workplace safety protocols across organisations throughout the UK. Safety managers should conduct thorough eye hazard assessments particularly for chemical splash risks, evaluate required eye injury treatment capability, determine appropriate kit sizes based on risk levels, and calculate kit quantities for multiple hazard areas. Kit selection should prioritise comprehensive contents appropriate to identified risks with emphasis on eyewash for chemical environments, organised layouts supporting emergency access, clear guidance materials, suitable containers for workplace conditions, and regulatory compliance particularly COSHH. Implementation protocols must encompass strategic kit placement in eye hazard areas ensuring immediate access, staff training on eye injury first aid and kit use, clear eye emergency procedures, and documented kit inspections. Quality assurance measures should include regular kit checks ensuring completeness, restocking procedures, expiry date monitoring particularly eyewash solutions, and incident recording. Modern eye care kit management may incorporate workplace eye incident analysis and kit optimisation. Organisations should establish eye emergency procedures specific to workplace hazards emphasising immediate irrigation for chemical splashes, integrate kits with broader safety provision, and maintain documentation. High-risk environments should implement enhanced eye safety measures including prevention, immediate treatment capability, and eyewash stations. Staff education should address eye hazard recognition, immediate response procedures particularly irrigation importance and duration, kit contents and use, and escalation to emergency care. By implementing eye care kits alongside professional protocols, organisations throughout England, Scotland, Wales, and Northern Ireland demonstrate commitment to workplace eye safety particularly in high-risk environments, comprehensive emergency response capability, professional preparedness, and effective organised eye injury treatment supporting optimal outcomes across all workplaces with significant ocular hazards.

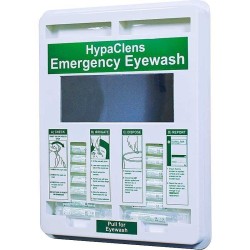

Eyewash Stations

Fixed Emergency Eye Irrigation for Immediate Chemical Response

Eyewash stations provide dedicated fixed or portable emergency eye irrigation equipment enabling immediate comprehensive eye washing following chemical splashes or contamination across laboratories, chemical handling facilities, manufacturing sites, and high-risk environments throughout England, Scotland, Wales, and Northern Ireland. These essential safety installations comprise wall-mounted or freestanding units delivering sterile irrigation solution through eye cups or nozzles, supporting immediate prolonged eye irrigation critical for chemical injury outcomes. High-risk organisations rely on eyewash stations for immediate chemical splash response, sustained eye irrigation capability, regulatory compliance particularly COSHH requirements, professional safety demonstration, and dedicated emergency response infrastructure. Modern eyewash stations incorporate features including readily accessible mounting positions, clear signage indicating locations, sufficient irrigation solution volumes, appropriate flow rates for effective washing, and user-friendly activation. The provision of eyewash stations demonstrates commitment to eye safety particularly in chemical environments, supports immediate sustained irrigation critical for chemical injury management, fulfils regulatory obligations, and enables professional emergency response across environments with significant chemical splash risks.

The implementation of eyewash stations directly supports workplace eye safety, chemical emergency response capability, and regulatory compliance in hazardous environments. Chemical eye injuries require immediate prolonged irrigation, with treatment delay significantly affecting outcomes including potential vision loss. Eyewash stations address these critical requirements by providing immediate irrigation capability at incident locations, enabling sustained washing removing contaminants, delivering appropriate solution volumes and flow rates, demonstrating regulatory compliance particularly COSHH requirements for chemical handling, and supporting professional emergency response. Applications include chemical laboratories requiring immediate splash response, manufacturing facilities with chemical processes, cleaning operations using hazardous substances, battery handling areas with acid splash risks, and workplaces with identified significant chemical eye hazards. Organisations benefit from eyewash stations through enhanced chemical injury outcomes via immediate sustained irrigation, demonstrated regulatory compliance, reduced liability through appropriate safety provision, and professional safety culture. Modern eyewash stations incorporate features such as hands-free operation, tempered water where plumbed, and testing mechanisms throughout England, Scotland, Wales, and Northern Ireland.

Selecting and implementing eyewash stations requires comprehensive chemical risk assessment, appropriate station specification, and integration with emergency response protocols across organisations throughout the UK. Safety managers should conduct thorough chemical risk assessments identifying splash hazards, determine required station locations based on hazard proximity and access time typically within ten seconds or ten metres, evaluate plumbed versus self-contained systems, and consider regulatory requirements particularly COSHH. Station selection should prioritise appropriate type with wall-mounted stations for fixed locations or portable units for flexibility, adequate irrigation volume and duration meeting standards typically fifteen minutes, suitable activation mechanisms enabling immediate hands-free use, appropriate mounting ensuring accessibility, and regulatory compliance. Implementation protocols must encompass strategic positioning near chemical hazards, clear signage indicating locations, staff training on eyewash station use, eye injury emergency procedures emphasising immediate irrigation, and documented maintenance. Quality assurance measures should include regular functional testing particularly for plumbed stations, documented inspection and testing schedules, solution replacement for self-contained units, maintenance ensuring continued functionality, and incident recording. Modern eyewash station management incorporates digital testing logs and preventive maintenance. Organisations should establish eye injury emergency procedures, integrate eyewash stations with broader chemical safety management, and maintain comprehensive documentation. Staff education should address eyewash station locations, immediate activation during chemical splashes, sustained irrigation importance typically fifteen minutes, and emergency services notification. Environmental considerations should ensure unobstructed access, appropriate drainage, and adequate lighting. By implementing eyewash stations alongside professional protocols, organisations throughout England, Scotland, Wales, and Northern Ireland demonstrate commitment to workplace eye safety in chemical environments, regulatory compliance with COSHH requirements, professional emergency response capability, and provision of critical infrastructure supporting optimal chemical eye injury outcomes across all workplaces with significant chemical splash hazards.

Eyewash Bottles and Pods

Portable Emergency Eye Irrigation for Immediate Response

Eyewash bottles and pods provide portable emergency eye irrigation solutions enabling immediate eye washing following chemical splashes, dust exposure, or contamination across workplaces, construction sites, mobile services, and varied environments throughout England, Scotland, Wales, and Northern Ireland. These convenient portable devices contain sterile saline or water for immediate eye irrigation, offering flexible emergency response capability where fixed eyewash stations are impractical. Organisations rely on eyewash bottles and pods for immediate portable eye irrigation, flexible emergency response in varied locations, supplementary provision near minor hazards, mobile work safety, and accessible first aid eye care. Modern eyewash bottles and pods incorporate features including sterile isotonic saline solutions, portable convenient sizes, integrated eye cups facilitating effective irrigation, clear instructions, and sealed packaging ensuring sterility until use. The provision of eyewash bottles and pods demonstrates commitment to comprehensive eye safety, supports immediate irrigation capability across varied locations, enables flexible emergency response, and fulfils duty of care across environments with eye contamination risks.

The implementation of eyewash bottles and pods supports flexible eye safety provision, immediate irrigation capability, and comprehensive emergency preparedness across varied locations. Whilst fixed eyewash stations provide optimal sustained irrigation for chemical splash scenarios, portable eyewash enables immediate response in varied locations and addresses less severe contamination. Eyewash bottles and pods address these needs by providing immediate portable irrigation capability, flexible provision for mobile work or multiple locations, appropriate response for dust or minor contamination, supplementary provision enhancing fixed station capability, and convenient first aid eye irrigation. Applications include construction sites requiring mobile eye safety provision, field work away from fixed facilities, workshops and maintenance areas with dust hazards, mobile services including emergency response and utilities, and first aid kits requiring eye irrigation capability. Organisations benefit from eyewash bottles and pods through flexible eye safety provision, immediate response capability across varied locations, cost-effective supplementary provision, and comprehensive eye injury preparedness. Modern eyewash products incorporate features such as ergonomic bottle designs, extended shelf life, and portable carrying options throughout England, Scotland, Wales, and Northern Ireland.

Selecting and implementing eyewash bottles and pods requires assessment of eye hazard locations, appropriate product specification, and integration with eye safety protocols across organisations throughout the UK. Safety managers should evaluate eye hazard distribution determining where portable provision is appropriate versus fixed stations, assess typical contamination scenarios, consider mobile or dispersed work requiring portable safety provision, and calculate adequate quantities. Product selection should prioritise sterile saline solutions providing appropriate irrigation, adequate volumes typically 500ml minimum, integrated eye cups or nozzles facilitating effective use, portable convenient packaging, and appropriate shelf life. Implementation protocols should encompass strategic placement in first aid kits and work areas, integration with eyewash station provision where applicable, staff training on eyewash use, eye injury emergency procedures, and documented supply management. Quality assurance measures should include regular supply checks, expiry date monitoring replacing solutions as needed, restocking procedures, and incident recording. Modern eyewash supply management may incorporate inventory tracking and automated reordering. Organisations should establish eye injury procedures differentiating scenarios requiring sustained irrigation via stations versus portable eyewash sufficiency, integrate eyewash provision with broader eye safety management, and maintain documentation. Staff education should address eyewash bottle locations and use, immediate irrigation importance, sustained washing for chemical splashes, and emergency services notification for serious injuries. Storage should protect eyewash supplies whilst ensuring accessibility. By implementing eyewash bottles and pods alongside appropriate protocols, organisations throughout England, Scotland, Wales, and Northern Ireland demonstrate commitment to comprehensive eye safety across varied locations, flexible emergency response capability, immediate irrigation provision, and professional eye injury management supporting optimal outcomes through accessible appropriate treatment across all working environments with eye contamination risks.

First Aid Eye Pads

Sterile Protection for Eye Injury Coverage

First aid eye pads provide essential sterile coverage for eye injuries following irrigation or treatment across workplaces, care facilities, emergency services, and first aid contexts throughout England, Scotland, Wales, and Northern Ireland. These specialist dressings comprise soft sterile pads designed specifically for eye coverage, protecting injured eyes from contamination whilst maintaining comfort during transport to medical care. Organisations rely on first aid eye pads for post-irrigation eye coverage, protection of injured eyes preventing contamination, comfortable secure dressing during emergency transport, infection prevention through sterile materials, and professional eye injury management. Modern first aid eye pads incorporate features including sterile packaging maintaining hygiene until use, soft materials providing comfortable eye coverage, appropriate sizes covering eyes completely, secure attachment methods typically bandages or adhesive surrounds, and individually wrapped units ensuring sterility. The provision of first aid eye pads demonstrates commitment to comprehensive eye injury care, supports appropriate emergency management following irrigation, enables professional first aid response, and fulfils duty of care across environments with eye injury risks throughout professional contexts.

The implementation of first aid eye pads directly supports workplace eye safety, appropriate post-injury management, and demonstration of comprehensive emergency preparedness. Eye injuries require irrigation followed by sterile coverage protecting eyes during transport to medical assessment, with appropriate coverage preventing contamination and secondary infection. First aid eye pads address these requirements by providing sterile protection following irrigation, comfortable coverage during emergency transport, infection prevention through appropriate materials, professional first aid capability, and integrated emergency response completing irrigation treatment. Eye injury applications include chemical splash management after irrigation, foreign object injuries requiring coverage, trauma requiring sterile protection, post-irrigation coverage in workplace incidents, and emergency transport preparation. Organisations benefit from eye pads through comprehensive eye injury management, demonstrated professional first aid capability, infection prevention through sterile coverage, and appropriate post-irrigation care. Modern eye pads incorporate features such as non-adherent surfaces, integrated bandages, and compact packaging throughout England, Scotland, Wales, and Northern Ireland.

Selecting and implementing first aid eye pads requires assessment of eye injury risks, appropriate product specification, and integration with eye injury protocols across organisations throughout the UK. Safety managers should evaluate eye injury scenarios determining eye pad requirements, assess typical incident patterns, consider integration with eyewash provision, and calculate adequate stock levels. Product selection should prioritise sterile individually wrapped pads ensuring hygiene, appropriate sizes providing complete eye coverage, comfortable soft materials, secure attachment methods, and adequate quantities based on risk assessment. Implementation protocols should encompass integration with eye care kits and first aid provision, staff training on eye pad application following irrigation, eye injury emergency procedures, and documented supply management. Quality assurance measures should include regular stock checks, expiry date monitoring ensuring sterility maintenance, storage protecting pad sterility, and incident recording. Modern eye pad supply management may incorporate inventory tracking integrated with broader first aid systems. Organisations should establish eye injury procedures including irrigation followed by sterile coverage application, integrate eye pads with comprehensive eye safety management, and maintain documentation. Staff education should address eye pad purpose following irrigation, correct application techniques ensuring coverage without pressure, securing methods, and recognition that eye pads support emergency management pending medical assessment. Storage should protect sterile packaging whilst ensuring accessibility within eye care supplies. By implementing first aid eye pads alongside professional eye injury protocols, organisations throughout England, Scotland, Wales, and Northern Ireland demonstrate commitment to comprehensive eye safety, appropriate post-irrigation management, infection prevention, and professional emergency response capability supporting optimal eye injury outcomes through sterile protective coverage during emergency care and transport across all working environments with ocular injury risks.